Due to a request by pa the brakes were the next thing to be looked after. Remanned calipers and new pads.. I had intended to also check and repack wheel bearings, though half way into the drivers side I wimped out and only did the calipers and pads.. (top picture is before, middle picture is after).. When I went around to the passenger side I discovered after removing the rim that the disk was hard to turn by hand... now I know that there is supposed to be some drag from the pads on the disk but this took a bit more than a general effort. I got the caliper off and discovered that the pads were wearing unevenly (bottom picture) The inside pad was wearing thin at the rear and the outside pad was wearing thin at the front. Seeing this i decided to dig a bit deeper into the wheel, I pulled the greese cap and discovered the nut on the bearing to be 'loose'.. like no tool required to remove it.. like so loose that I was able to tighten it by hand.. That got me to thinking 'boy I hope the bearings aren't screwed up. so I pulled that side apart the rest of the way and cleaned all the parts good in some gas.. I am happy to say the bearings and races look o.k.. I will get a couple new greese seals (and a grease gun and perhaps a bearing paking tool for it) and repack the right front.. before returning to the left front and dissasembling/repacking it for good measure. Perhaps I will also call up the Muffler and Brake shop to see how much disk resurfacing would run..

Due to a request by pa the brakes were the next thing to be looked after. Remanned calipers and new pads.. I had intended to also check and repack wheel bearings, though half way into the drivers side I wimped out and only did the calipers and pads.. (top picture is before, middle picture is after).. When I went around to the passenger side I discovered after removing the rim that the disk was hard to turn by hand... now I know that there is supposed to be some drag from the pads on the disk but this took a bit more than a general effort. I got the caliper off and discovered that the pads were wearing unevenly (bottom picture) The inside pad was wearing thin at the rear and the outside pad was wearing thin at the front. Seeing this i decided to dig a bit deeper into the wheel, I pulled the greese cap and discovered the nut on the bearing to be 'loose'.. like no tool required to remove it.. like so loose that I was able to tighten it by hand.. That got me to thinking 'boy I hope the bearings aren't screwed up. so I pulled that side apart the rest of the way and cleaned all the parts good in some gas.. I am happy to say the bearings and races look o.k.. I will get a couple new greese seals (and a grease gun and perhaps a bearing paking tool for it) and repack the right front.. before returning to the left front and dissasembling/repacking it for good measure. Perhaps I will also call up the Muffler and Brake shop to see how much disk resurfacing would run..

EDIT: Here is the information I will be using from a 67-69 Thunderbird Manual I found online.

Read part two here

Sunday, November 25, 2007

'Dems da brakes

Friday, November 16, 2007

It's exhausting

The mufflers and truly the entire exhaust system on this Thunderbird was rotten. I had thought about only having done what was missing. For a while. I did eventually decide to have a completely new exhaust system created.

The first place I called (Midas) didn't have a bender on site and would have to get a kit shipped to them to install. No thanks.. The second place I called did have a bender on site but using it wasn't something that he did very often and so he wasn't comfortable providing me service. Kens Auto Service however did recommend me to Green Muffler and Brake Shop. I called Green and talked with John there and he wasn't afraid at all. We talked briefly about what I was looking for in terms of gauge, diameter and mufflers etc. He wanted to make a call to see if there was a kit available and called me back within a few minutes with a quote for a custom bent and welded system since there was no prefabbed kit available.

The system includes the heaviest(OEM type) pipe, the 'H' pipe, two high performance Magnaflow 11225 mufflers and two new exhaust donuts.

I drove the Bird across town to Green Muffler and Brake Shop on Wednesday morning, paid the tab at noon on Friday, and picked it up after work on Friday. The total came to $499.29.. Money well spent.

It sounds better than it did.

Saturday, November 10, 2007

UPDATE: Turn Signals and brake lights

Ahh sunny fall Saturday afternoons are sure great things.

Replacing the turn signal switch had some effects on other road worthy deficiencies of the bird bird. Turn signals and brake lights. Here is a bit of video I shot after I came back from my short drive.

Chief Running Carb

This poor thing sat for two years with gasoline both in the tank as well as the carburetor. I could tell on the drive from west to east that I took it on. Even if you tried to get it just over idle it would nearly die.

Last night after work I took the top of the Edlebrock carb apart and was appalled at the amount of orange brown slime in the bottom of the side tanks. The valve in the accelerator pump circuit was completely stuck. I pulled everything apart and hosed it all down with carb cleaner. While I was putting it back together I manually tried the accelerator pump and was rewarded by seeing two nice fat streams of fuel pouring forth from the both jets. I went ahead and continued to get it all put back together.. and since it was midnight or so, called it quits for the night.

This afternoon, after the football game (GOOO HUSKERS!!!) I pulled it out of the garage.. and since it is missing some serious exhaust made a whole pile of racket. Thing were a little dicey getting it to move from a stop at first (must have been a lot of stuff on the spark plugs to burn off) but by the time I brought it back to the house I once again had pretty instant throttle response. Rumpaa Rumpaa... hehe.. Some time during this next week I plan to get it up to Midas for a quote and perhaps get some new pipes and new mufflers put on it. Then I can actually start driving it a little without waking up the entire neighborhood.

Next update will include a bit of video I shot after returning from my short drive. Stay tuned.

Thursday, November 8, 2007

Window to the world

The windows in these Thunderbirds were glued into the tracks from the factory. Then the tracks were bolted into the window mechanism itself. After thirty some years (or twenty) the tracks come loose from the glass and things get sloppy. Back when I was driving this beast full time I had used a product from Duramix to glue things back together. It usually stayed put for about six months before coming loose again. This time around I decided I was going to have it professionally fixed.

If you haven't ever removed the door glass out of your Thunderbird (which I find REALLY hard to believe) it is really pretty simple. Put the window up at about six inches (figure A) and remove the arm rest and door panel. From there it is two bolts holding the rear guide onto the track (figure C) , two bolts holding the front guide onto the track, one nut at the pivot point with the window mechanism and one bolt holding the front stop onto the track (Figure B) . After those have been removed the glass and track assembly can be lifted (carefully) out of the door.

I pulled both windows out and took them all down to Auto Glass Center here locally. Figuring "hey, they are the Auto Glass Center they should know how to fix these the best".. Well I'm not to sure about that.. In talking with the guys in the shop about the positioning of the tracks on the glass I said "You guys probably have a book?".. *chuckle*.. no they didn't.. they used the same stuff they use to glue in windshields with (can't hardly think that will hold for very long) and they didn't get the glass pushed all the way into the channel.. Soo all in all I wasn't very impressed with the service.. The only thing I WAS impressed with was the price.. at 20 bucks I can simply try somewhere else when they come loose in the future. No big deal.

Friday, November 2, 2007

Turn Signal Switch R&R

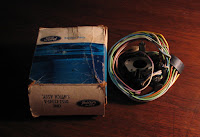

The turn signal switches in these early '70s Thunderbirds are prone to plastic fatigue. There are more readily available and cheaper alternatives on the market but I highly recommend that faced with the same need you choose to find a NOS complete turn signal as I have. This was found on Ebay (figure A)from a good parts seller there and was purchased for less than thirty dollars.

The first thing that needs to be done to switch out the switch is to remove the wire connectors from the pigtail, in my application it wasn't going to be necessary for me to plug them back into this block but you might need to. Please note the position on color coding of each wire.. maybe take a few good digital photographs of it. They will come in handy.

After you have removed the connectors and placed them in a safe location (if you will be reusing them) or tossed them in a box (as I did) bundle up the wires (figure C) and tape them all together. This will make it easy to thread them down inside of the column later.

Set switch aside.

Next we will get inside of the car, remove the steering wheel as you can see I swapped in a grant Steering wheel (figure D) back when I was driving it so I won't bore you with the removal of it since this will more than likely be different from your application.

Once the steering wheel has been removed you should be looking at something similar to figure E. Don't be intimidated by the mess of wiring, most of this will come out for us. Remove the turn signal lever. The actual switch is held in place by three screws, remove them and set them aside. Pull the switch up and away from the shaft and flop it towards you. Figure F. Cut the wires off of the switch being careful not to slice the other wires inside of the column, they go to the gear selector display and the ignition switch and are not included in the switch. Bundle the wires off the old switch together and secure them with tape. Take the wires from the new switch and tape them to the end of the wires off the old switch. Dive under the dash and determine which wires going up the column are going to the switch. Once you have determined which wires they are pull old wires down out of the column dragging the new wires along with. Positioning the switch over the the shaft as you do. Figure G. from this point on it is a simple process of replacing the wires back into the new connectors, removing the old wires, plugging everything back in and reassembling the steering wheel.

Wasn't quite that simple for me.

The wires that were attached to my switch were about 10 inches to short to make it to the wire harness so I had to splice the wires together. That meant that I needed to cut open the sheath the wire ends were in (Figure H) splice them together and tape up the sheath to protect the wires.

I got through it just fine though. Even brought the original steering wheel out of it's retirement in trunk. Figure I. I think it looks nice.

Thursday, November 1, 2007

Thunderbird Parts / Service List

Turn Signal Switch

Turn Signal SwitchThe turn signal switches in these early '70s Thunderbirds are prone to plastic fatigue. There are more readily available and cheaper alternatives on the market but I highly recommend that faced with the same need you choose to find a NOS complete turn signal as I have. This was found on Ebay from a good parts seller there and was purchased for less than thirty dollars. READ THE INSTALATION HERE

The windows in these Thunderbirds were glued into the tracks from the factory. Then the tracks were bolted into the window mechanism itself. After thirty some years (or twenty) the tracks come loose from the glass and things get sloppy. Back when I was driving this beast full time I had used a product from Duramix to glue things back together. It usually stayed put for about six months before coming loose again. This time around I decided I was going to have it professionally fixed. READ THE POST HERE

Shortly before the bird was parked I had from the muffler back fall off of the car while at Interstate speeds. One of the jobs to be done after bringing it out of retirement was to have the exhaust system looked after. READ THE POST HERE

Sure it ran, but it just didn't run all that great. The plug wires were old and the points were used up so it was time to not only replace some key parts but also do a little bit of upgrading at the same time. READ THE POST HERE

Sure it ran, but it just didn't run all that great. The plug wires were old and the points were used up so it was time to not only replace some key parts but also do a little bit of upgrading at the same time. READ THE POST HERE